- Products

- HD FLEXO Printing

HD FLEXO Printing

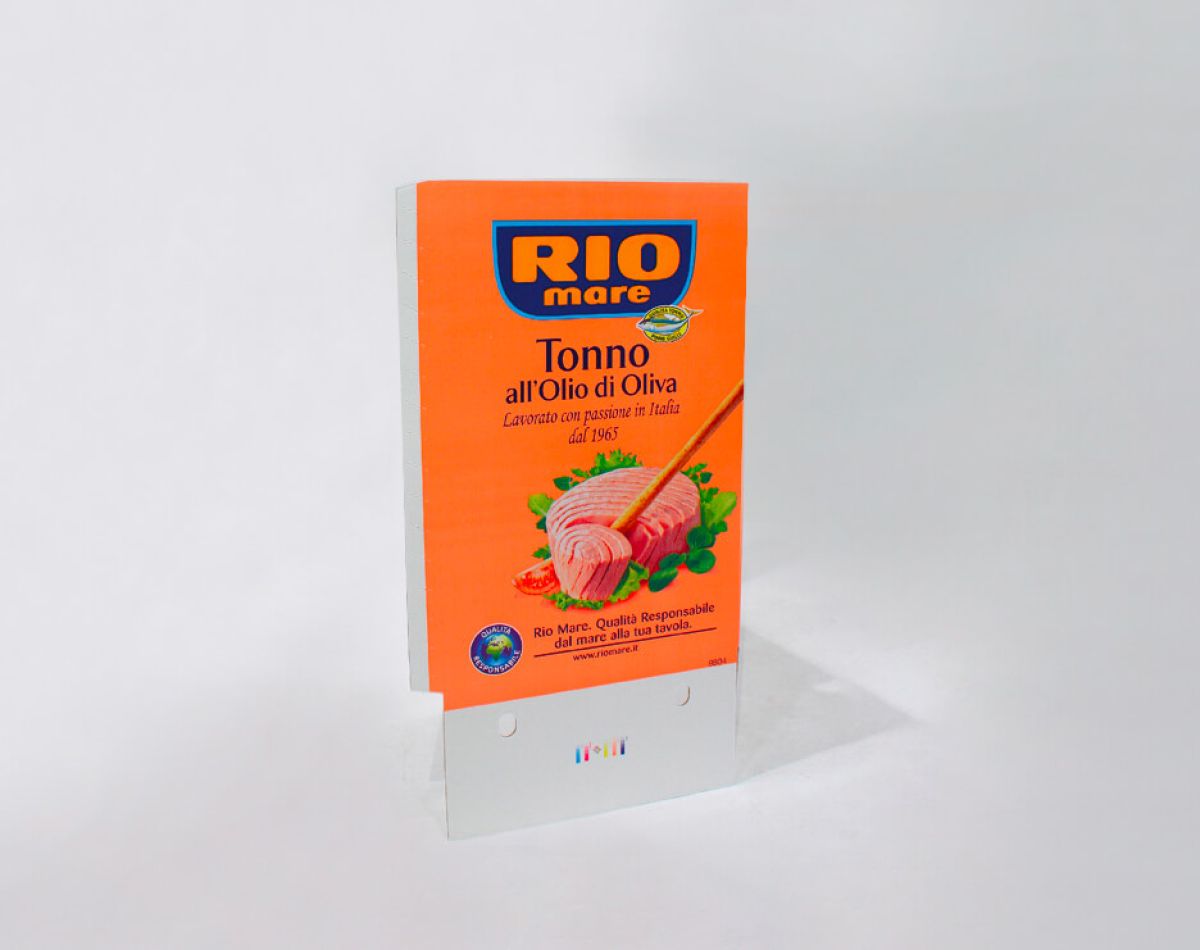

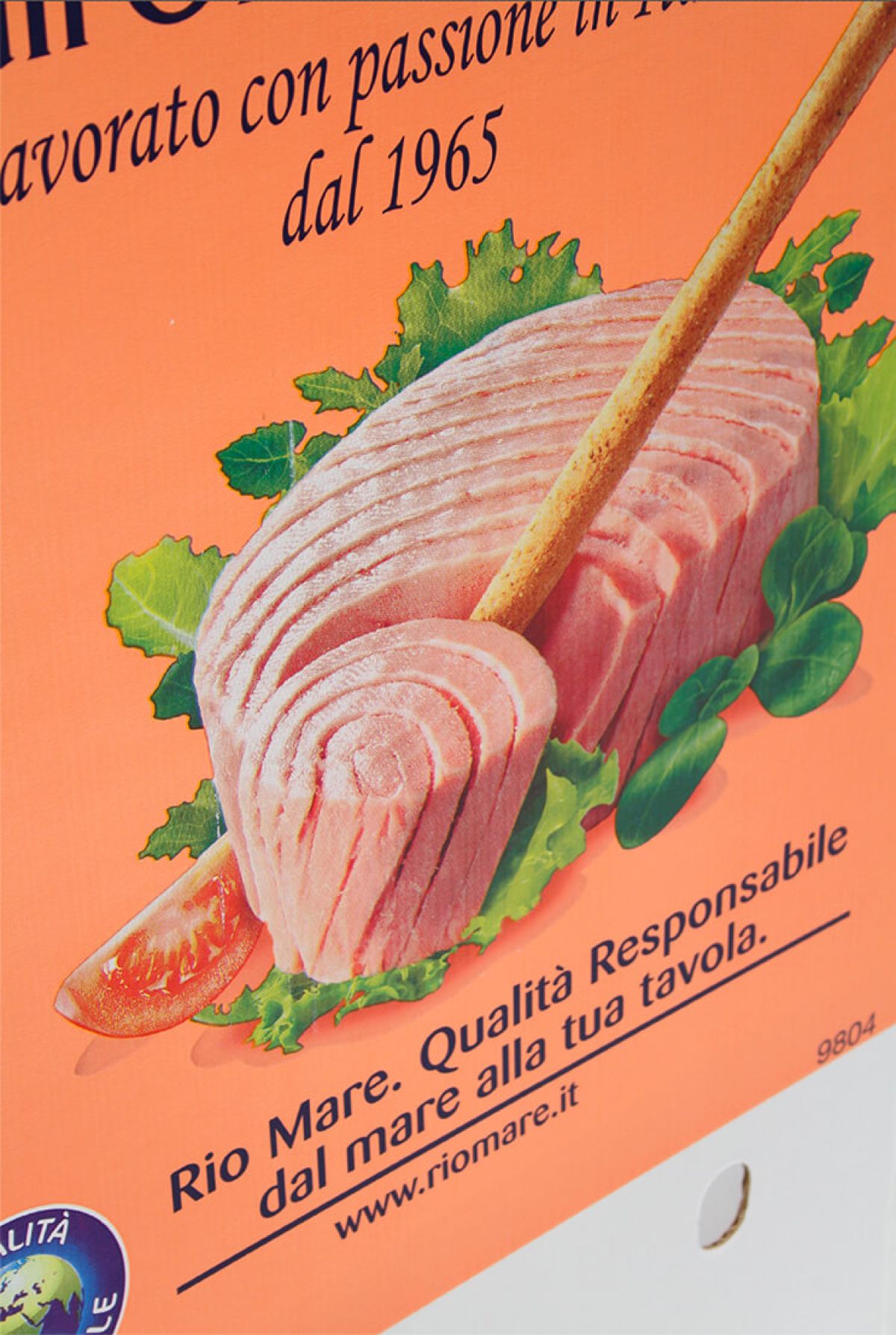

With flexographic printing, it’s possible to customize corrugated cardboard boxes with high-quality graphics. Today, flexographic printing ensures detailed results, offering an excellent balance between cost and production efficiency. This type of printing is also distinguished by reduced processing times and fast drying, making it particularly suitable for large production runs.

Flexo – as it is commonly known – uses flexible plates, called clichés, which transfer ink directly onto the cardboard through rotating rollers (direct rotary printing). An anilox roller precisely meters the ink, ensuring an even distribution. The inks used are all water-based, completely safe for consumers and the environment.

Flexographic printing works very well on surfaces like corrugated cardboard. Euroscatola prints on both kraft cardboard and white matte or coated cardboard. Our state-of-the-art equipment allows us to print up to 4 colors plus varnish or up to 5 high-definition colors.

We can also print 4 colors on the outside and 1 on the inside in a single pass, thanks to a cutting-edge machine for front-and-back printing. The main advantage of this machine is its speed. Further reduction in processing time also leads to a reduction in waste and production costs associated with machine operation—important elements for the product’s sustainability.

It’s possible to print on the box information about the product’s usage, origin, and composition, as well as – and most importantly – creative elements such as graphics, images, or high-impact patterns. The result of flexographic printing is high-quality and tailored to meet any communication and branding needs.